About us

Krishna Engineering Works is a distinguished name in the manufacturing of brake parts, springs, sheet metal parts, and funner sheet metal components. Established with a commitment to precision and quality, we have been serving the automotive industry with excellence for the past 50 years. For our company, quality is the top priority in all our operations.

Our manufacturing processes adhere to strict quality control measures, ensuring that each product meets international standards. Rigorous testing procedures guarantee durability, reliability, and optimal functionality. For over 50 years, we have been dedicated to providing our customers with precision-engineered components that meet the most stringent quality standards.

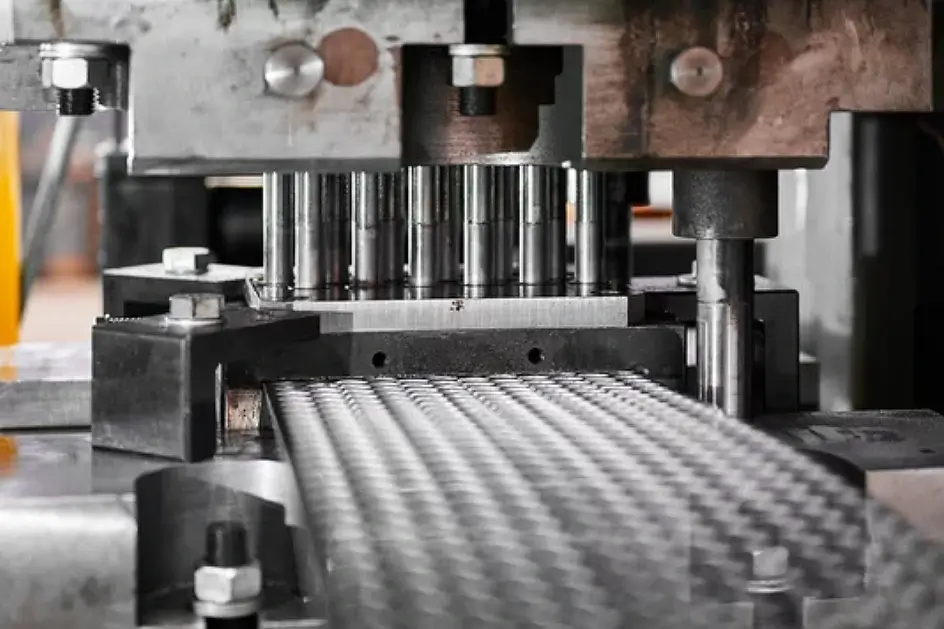

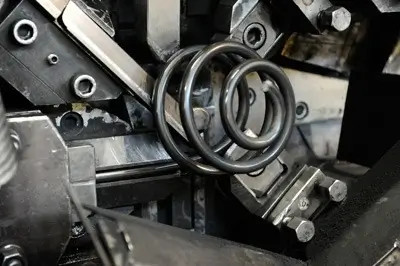

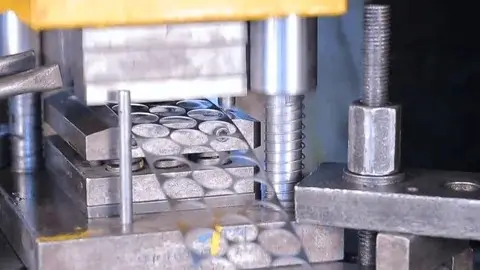

Our state-of-the-art manufacturing facility is equipped with advanced machinery and a highly skilled workforce, enabling us to produce a wide range of sheet metal parts and springs that cater to various industries, including the automotive sector.

At Krishna Engineering Works, we pride ourselves on our commitment to excellence, ensuring that every product we deliver meets or exceeds customer expectations. Our capabilities include:

- Sheet Metal Parts : We manufacture brake adjusters, brake disc pad locks (also known as caliper clips or spring pad clips), caliper pin kits, and more for the automotive industry. Additionally, we produce various sheet metal parts according to customer requirements.

- Springs Manufacturing : We produce a wide range of springs, including coil springs (also known as suspension springs), brake shoe springs, compression springs, tension springs, torsion springs, and customized springs based on customer needs.

- Quality Assurance : We implement stringent quality control processes to ensure that all products are reliable and meet industry standards.

- Timely Delivery : Our efficient production processes ensure on-time delivery, regardless of order size.

Our Mission

Our mission at Krishna Engineering Works is to deliver precision-engineered brake parts, springs, and sheet metal components that exceed industry standards and customer expectations. We are committed to maintaining the highest levels of quality, innovation, and reliability in our manufacturing processes while fostering long-term relationships with our customers through excellence and trust.

Vision

Our vision is to be a global leader in the automotive component manufacturing industry, recognized for our uncompromising quality, advanced technology, and customer-centric approach. We aim to continually innovate and expand our capabilities to meet the evolving needs of the automotive sector and other industries we serve.

Values

- Quality : We prioritize precision and excellence in every product we manufacture, ensuring adherence to international standards.

- Integrity : We operate with transparency, honesty, and reliability in every aspect of our business.

- Innovation : We are committed to investing in advanced technologies and processes to continuously improve our manufacturing capabilities.

- Customer Satisfaction : Meeting and exceeding customer expectations is at the core of our operations.

- Sustainability : We are dedicated to implementing eco-friendly practices in our manufacturing processes to minimize environmental impact.

Objectives

- To continually improve and innovate our manufacturing processes to maintain the highest levels of product quality and durability.

- To ensure timely and efficient delivery of all products, regardless of order size, through streamlined production processes.

- To expand our product range and capabilities, catering to the growing needs of the automotive and other industries.

- To build lasting relationships with our customers through exceptional service and reliable, precision-engineered components.

- To uphold rigorous quality control measures, ensuring every product meets international standards for reliability and performance.